SS 304 & 316 Chitsulo Chosapanga Zitsulo Zosapanga Zitsulo Zoyera

Ma SS 304 ndi 316 Stainless Steel Sanitary Pipe Fittings athu adapangidwa kuti akwaniritse zofunikira kwambiri zaukhondo wa chakudya ndi zakumwa, mankhwala, sayansi ya zamoyo, ndi zokongoletsa. Monga zinthu zofunika kwambiri mu machitidwe aukhondo a mapaipi, zigongono, ma tee, ndi zolumikizira izi zolondola zimaonetsetsa kuti zinthuzo ndi zoyera, zimapewa kuipitsidwa, komanso zimathandiza kuti njira zoyeretsera zikhale zogwira mtima.

Zopangidwa kuchokera ku chitsulo chosapanga dzimbiri cha AISI 304 kapena chitsulo chosapanga dzimbiri cha 316/316L chosagwira dzimbiri, zolumikizira izi zili ndi mapangidwe opanda mipata yokhala ndi malo opukutidwa mkati omwe amaposa miyezo yamakampani kuti ayeretsedwe. Zimapezeka ndi njira zingapo zolumikizira kuphatikiza Tri-Clamp ndi orbital butt weld, zimapereka mayankho osiyanasiyana pazokhazikitsa zokhazikika komanso machitidwe omwe amafunikira kuchotsedwa pafupipafupi kuti akonze kapena kusintha ma batch. Cholumikizira chilichonse chapangidwa popanda miyendo yofa kuti chiteteze mabakiteriya ndipo chimagwirizana kwathunthu ndi njira za Clean-in-Place (CIP) ndi Sterilize-in-Place (SIP), kuonetsetsa kuti zikutsatira malamulo apadziko lonse lapansi aukhondo ndi zofunikira za GMP.

Tsamba lazambiri

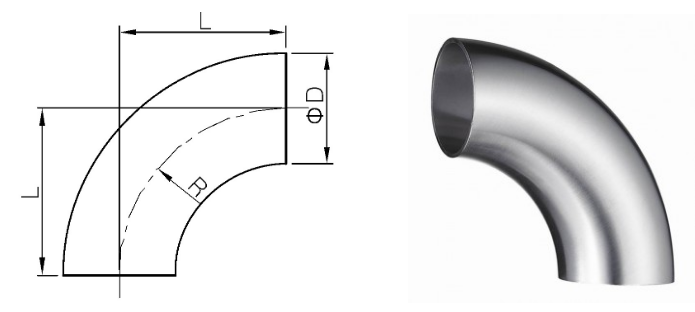

Kukula kwa Chigongono Chosenda Chaukhondo 90 digiri -3A (gawo:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1/1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

Kukula kwa chigongono cha Sanitary Weld 90 digiri -DIN (Unit:mm)

| SIZE | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

Kukula kwa chigongono cha Sanitary Weld 90 digiri -ISO/IDF (Unit:mm)

| SIZE | D | L | R |

| 12.7 | 12.7 | 19.1 | 19.1 |

| 19 | 19.1 | 28.5 | 28.5 |

| 25 | 25.4 | 33.5 | 33.5 |

| 32 | 31.8 | 38 | 38 |

| 38 | 38.1 | 48.5 | 48.5 |

| 45 | 45 | 57.5 | 57.5 |

| 51 | 50.8 | 60.5 | 60.5 |

| 57 | 57 | 68 | 68 |

| 63 | 63.5 | 83.5 | 83.5 |

| 76 | 76.2 | 88.5 | 88.5 |

| 89 | 89 | 103.5 | 103.5 |

| 102 | 101.6 | 127 | 127 |

| 108 | 108 | 152 | 152 |

| 114.3 | 114.3 | 152 | 152 |

| 133 | 133 | 190 | 190 |

| 159 | 159 | 228.5 | 228.6 |

| 204 | 204 | 300 | 300 |

| 219 | 219 | 305 | 302 |

| 254 | 254 | 372 | 375 |

| 304 | 304 | 450 | 450 |

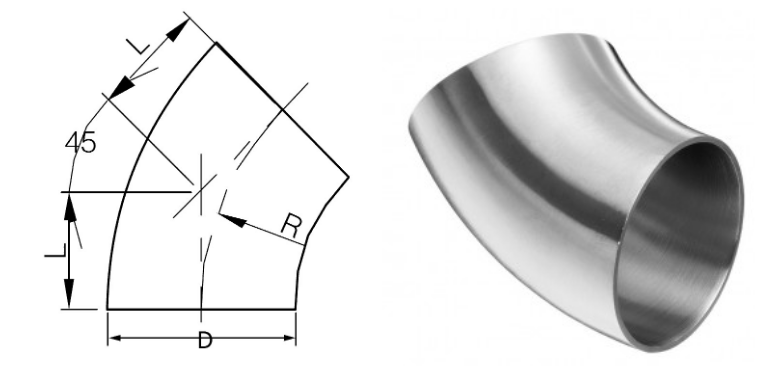

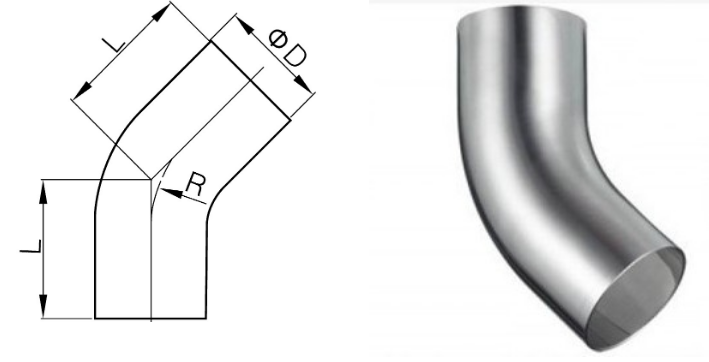

Kukula kwa Chigongono Chosenda cha Santitary Weld - madigiri 45 -3A (gawo:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 7.9 | 19.1 |

| 3/4" | 19.1 | 11.8 | 28.5 |

| 1" | 25.4 | 15.8 | 38.1 |

| 1 1/4" | 31.8 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 74.1 | 57.2 |

| 2" | 50.8 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 131.8 | 95.3 |

| 3" | 76.2 | 160.3 | 114.3 |

| 4" | 101.6 | 211.1 | 152.4 |

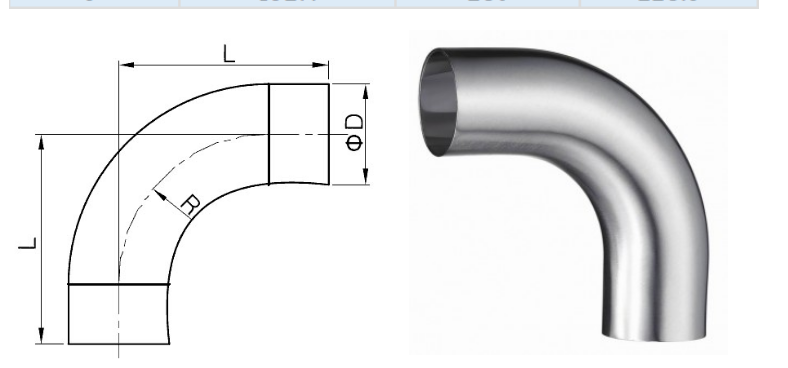

Kukula kwa Chigongono Chosenda cha Ukhondo - madigiri 90 -3A (gawo:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

Kukula kwa Chigongono Chosenda cha Santitary Weld - madigiri 45 Ndi Mapeto Olunjika -SMS (Unit:mm)

| SIZE | D | L | R |

| 25 | 25.4 | 45 | 25 |

| 32 | 31.8 | 53.3 | 32 |

| 38 | 38.1 | 56.7 | 38 |

| 51 | 50.8 | 63.6 | 51 |

| 63 | 63.5 | 80.8 | 63.5 |

| 76 | 76.2 | 82 | 76 |

| 102 | 101.6 | 108.9 | 150 |

KUYESA

Zofunika:

AISI 304 (CF8): 18-20% Chromium, 8-10.5% Nickel – Kukana dzimbiri bwino kwambiri

AISI 316/316L (CF3M): 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum - Kukana kwabwino kwa chloride

Chitsimikizo cha Zinthu: Zipangizo zonse zimaperekedwa ndi satifiketi ya EN 10204 3.1 komanso kutsata kwathunthu

Mitundu Yotsika ya Kaboni: 316L (<0.03% C) ikupezeka pa ntchito zomwe zimafuna kusinthasintha kwabwino

Zinthu Zokhudza Kapangidwe ka Ukhondo:

Kapangidwe ka Miyendo Yopanda Kufa: Ma radii amkati ≤1.5D pa zofunikira za ASME BPE

Kapangidwe Kopanda Ming'alu: Malo opukutidwa mosalekeza okhala ndi ma radii osachepera 3mm

Geometry Yotulutsa Madzi: Makona odzichotsera madzi okha amaletsa madzi kulowa m'khola

Kusintha Kosalala: Kusintha pang'onopang'ono kwa njira kuti muchepetse kusokonezeka

Yosawiritsa: Yovomerezeka pa nthawi yobwerezabwereza yoyeretsa nthunzi

Ubwino Wopanga Zinthu:

Kupanga Moyenera: Kupanga kozizira kapena kupanga hydroforming kuti makoma akhale olimba nthawi zonse

Kuwetera kwa Orbital: Kwa zolumikizira za butt weld, kuonetsetsa kuti zilowa bwino popanda kutentha kwambiri

Kupukuta Kopita Patsogolo: Kupukuta kwa makina kwa magawo ambiri (180-600+ grit sequence)

Kupukuta ndi Electrochemical: Njira yosankha yamagetsi yolimbikitsira kukana dzimbiri

Kuchepetsa: Chithandizo cha nitric acid pa ASTM A967 kuti abwezeretse chromium oxide wosanjikiza

Machitidwe Olumikizirana:

Chitseko Chokhala ndi Katatu: Chitseko chokhazikika cha 1.5" chokhala ndi ma ferrule opukutidwa a 304/316

Kulukana kwa Butt: Malekezero okonzedwa kuti agwiritsidwe ntchito polukana kwa orbital (kulinganiza kwa ID/OD mkati mwa 0.1mm)

Mpando wa Bevel: Kulumikizana kwa ISO komwe kumasunga gasket mwaukhondo

Kuchotsa Mwachangu: Kulumikiza kwa Aseptic kuti musonkhanitse/kuchotsa zinthu pafupipafupi

Kulemba ndi Kutsata Ubwino:

Kulemba kwa Laser: Kulemba kosatha ndi kalasi ya zinthu, kukula, ndi nambala ya malo

Kulemba Makhodi a Mitundu: Mabatani amitundu omwe mungasankhe kuti muzindikire mosavuta m'makina osakanikirana

Kulemba RFID: Kumapezeka pamakina osungiramo zinthu ndi kutsata zinthu zokha

Kugwiritsa ntchito

Machitidwe a Madzi:

Ma WFI (Madzi Opangira Injection) ndi ma PW (Madzi Oyeretsedwa) ogawa

Akatswiri a zamoyo:

Kukonzekera kwa media, kukolola, ndi zitsanzo

Machitidwe Oyeretsera:

Makina otsetsereka a chromatography ndi makina oyeretsera a ultrafiltration

Kupanga:

Kukonzekera kwa buffer ndi mizere yosamutsira zinthu

Mpweya Woyera:

Machitidwe osonkhanitsira ndi kugawa ma condensate

Q: Kodi mungalandire TPI?

A: Inde, inde. Takulandirani ku fakitale yathu ndipo bwerani kuno kudzayang'ana katunduyo ndikuwona momwe amapangira.

Q: Kodi mungapereke Fomu e, Satifiketi yoyambira?

A: Inde, tikhoza kupereka.

Q: Kodi mungapereke invoice ndi CO ku chipinda cha zamalonda?

A: Inde, tikhoza kupereka.

Q: Kodi mungavomereze L/C yochedwa masiku 30, 60, kapena 90?

A: Tingathe. Chonde kambiranani ndi ogulitsa.

Q: Kodi mungalandire malipiro a O/A?

A: Tingathe. Chonde kambiranani ndi ogulitsa.

Q: Kodi mungapereke zitsanzo?

A: Inde, zitsanzo zina ndi zaulere, chonde funsani ngati pali malonda.

Q: Kodi mungapereke zinthu zomwe zikugwirizana ndi NACE?

A: Inde, tingathe.

Zipangizo zolumikizira mapaipi ndi zinthu zofunika kwambiri mu dongosolo la mapaipi, zomwe zimagwiritsidwa ntchito polumikiza, kusinthira, kusintha kukula, kutseka kapena kuwongolera kayendedwe ka madzi. Zimagwiritsidwa ntchito kwambiri m'magawo monga zomangamanga, mafakitale, mphamvu ndi ntchito za m'matauni.

Ntchito Zofunika Kwambiri:Imatha kugwira ntchito monga kulumikiza mapaipi, kusintha njira yoyendera, kugawa ndi kuphatikiza madzi oyenda, kusintha mainchesi a mapaipi, kutseka mapaipi, kuwongolera ndikuwongolera.

Chiwerengero cha Ntchito:

- Kupereka madzi ndi ngalande m'nyumba:Zigongono za PVC ndi ma PPR tris amagwiritsidwa ntchito pa maukonde a mapaipi amadzi.

- Mapaipi a mafakitale:Ma flange achitsulo chosapanga dzimbiri ndi zigongono zachitsulo chopangidwa ndi alloy zimagwiritsidwa ntchito kunyamula zinthu zamagetsi.

- Kuyendera mphamvu:Mapaipi achitsulo amphamvu kwambiri amagwiritsidwa ntchito m'mapaipi amafuta ndi gasi.

- HVAC (Kutenthetsa, Kupumira mpweya, ndi Kuziziritsa Mpweya):Zipangizo za mapaipi a mkuwa zimagwiritsidwa ntchito polumikiza mapaipi oziziritsa, ndipo malo olumikizirana osinthasintha amagwiritsidwa ntchito pochepetsa kugwedezeka.

- Ulimi wothirira:Zolumikizira mwachangu zimathandiza kusonkhanitsa ndi kusokoneza makina othirira opopera madzi.

-

chopachika chopanda kanthu A515 gr 60 figure 8 spectac...

-

fakitale DN25 25A sch160 90 digiri chigongono chitoliro fi ...

-

304 316 Zosapanga dzimbiri Zopanda Ukhondo za Pneumatic Actuated B ...

-

Chitoliro cha chigongono cha 1″ 33.4mm DN25 25A sch10 chogwirira ...

-

Chitoliro cha ASTM Standard 304/316/316L Chitsulo Chosapanga Dzimbiri ...

-

chitsulo cha kaboni chotulutsa khosi mtundu wa 6″ ANSI CLASS ...