Flange Yopangidwa ndi Chitsulo Chosapanga Dzimbiri Chopangidwa ndi 304/316L

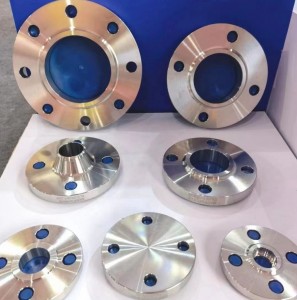

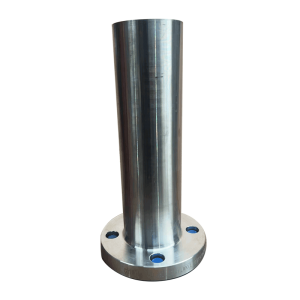

Flange ya Standard Pressure Orifice Flange yopangidwa kuchokera ku chitsulo chosapanga dzimbiri cha 304/316L imayimira gawo loyezera kuyenda bwino lomwe lapangidwira ntchito zofunika kwambiri. Flange izi zimapangidwa mwapadera kuti zipereke muyeso wolondola, wodalirika, komanso wobwerezabwereza wa kuyenda kwa madzi m'mafakitale apaipi pomwe zimasunga umphumphu wa kapangidwe kake pansi pa mikhalidwe yosiyanasiyana ya kupanikizika. Yopangidwa kudzera mu njira zapamwamba zopangira ndi makina olondola, ma flange athu a orifice amatsimikizira magwiridwe antchito abwino kwambiri mu ntchito zowononga komanso zoyera kwambiri komwe umphumphu wa zinthu ndi kulondola kwa magawo ndizofunikira kwambiri.

Kalasi 150: Yoyenera kugwiritsa ntchito mphamvu zochepa (275 psi pa 100°F)

Kalasi 300: Kugwiritsa ntchito mphamvu yapakati (720 psi pa 100°F)

Kalasi 600: Kugwiritsa ntchito mphamvu yothamanga kwambiri (1,440 psi pa 100°F)

Kalasi 900: Kugwiritsa ntchito mphamvu kwambiri (2,160 psi pa 100°F)

Kulipira Kutentha: Kuchuluka kwa kutentha komwe kulipo pakugwiritsa ntchito kutentha kwakukulu

ZOCHITIKA ZAMBIRI ZOGWIRITSA NTCHITO CHIWONETSERO

Miyezo Yoyambira:

ASME B16.36, ASME B16.5, API 6A

Miyezo Yachiwiri:

MSS SP-44, ISO 7005-1, DIN 2527

Kuchuluka kwa Kupanikizika ndi Kutentha:

Yogwirizana kwathunthu ndi ASME B16.5 Table 2-1.1

Miyezo Yofunika:

ASTM A182 F304/F304L, F316/F316L

KULEMBA NDI KUPAKIRA

• Gawo lililonse ligwiritse ntchito filimu ya pulasitiki kuti liteteze pamwamba pake

• Pazitsulo zonse zosapanga dzimbiri, zimayikidwa ndi bokosi la plywood. Kuti flange ya carbon ikhale yayikulu, imayikidwa ndi plywood pallet. Kapena ikhoza kukonzedwa mwamakonda.

• Chizindikiro chotumizira chingapangidwe ngati pakufunika

• Zolemba pa zinthu zitha kujambulidwa kapena kusindikizidwa. OEM yalandiridwa.

KUYENDA

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Kuyesa kukula

Gulu lathu la QC lidzakonza mayeso a NDT ndikuwunika kukula kwake. Lidzavomerezanso TPI (kuyang'aniridwa ndi chipani chachitatu).

NJIRA YOPANGIDWA

| 1. Sankhani zinthu zenizeni zopangira | 2. Dulani zinthu zopangira | 3. Kutentha koyambirira |

| 4. Kupangira | 5. Kuchiza kutentha | 6. Makina Ovuta |

| 7. Kuboola | 8. Kukonza bwino | 9. Kulemba |

| 10. Kuyendera | 11. Kulongedza | 12. Kutumiza |

Njira Yopangira: Ukadaulo Wopangira Molondola

Njira Yopangira Yotsekedwa

- Kusankha Zinthu: Ma billets achitsulo chosapanga dzimbiri apamwamba kwambiri okhala ndi kutsata kwathunthu

- Njira Yotenthetsera: Kutentha koyendetsedwa ndi induction kufika pa 1150-1260°C

- Ntchito Yopangira: Kupanga masitepe ambiri pansi pa makina osindikizira a matani 2,500-6,000

- Kukonza Kuyenda kwa Tirigu: Kuyenda kwa tirigu molunjika kuti zinthu zikhale bwino pamakina

- Kuchotsa Sikelo: Kuchotsa madzi othamanga kwambiri kuti malo oyera akhale oyera

Ndondomeko Yothandizira Kutentha

- Kuthira Madzi: Kutentha mpaka 1010-1120°C kutsatiridwa ndi kuzimitsa mwachangu

- Kuchepetsa Kupsinjika Maganizo: Kwa ma geometri ovuta komanso magawo olemera

- Kutenthetsa: Pakufunika zinthu zinazake zamakina

- Kuzimitsa Zinthu: Madzi, mafuta, kapena mpweya malinga ndi zofunikira za zinthu

Ntchito Zopangira Machining Molondola

- Kutembenuza kwa CNC: Makina oyambira nkhope ndi chibowo

- Kuboola Mabowo a Bolt: Kuboola kolondola pogwiritsa ntchito zida za carbide

- Kupukuta Nkhope: Kumaliza kokhala ndi mano (125-250 AARH) kuti pakhale mipando yabwino kwambiri ya gasket

- Kukonza Machining a Orifice Bore: Kusalolera pang'ono (± mainchesi 0.001)

- Kuyang'anira Komaliza: Kutsimikizira kwathunthu kwa magawo

Q: Kodi mungalandire TPI?

A: Inde, inde. Takulandirani ku fakitale yathu ndipo bwerani kuno kudzayang'ana katunduyo ndikuwona momwe amapangira.

Q: Kodi mungapereke Fomu e, Satifiketi yoyambira?

A: Inde, tikhoza kupereka.

Q: Kodi mungapereke invoice ndi CO ku chipinda cha zamalonda?

A: Inde, tikhoza kupereka.

Q: Kodi mungavomereze L/C yochedwa masiku 30, 60, kapena 90?

A: Tingathe. Chonde kambiranani ndi ogulitsa.

Q: Kodi mungalandire malipiro a O/A?

A: Tingathe. Chonde kambiranani ndi ogulitsa.

Q: Kodi mungapereke zitsanzo?

A: Inde, zitsanzo zina ndi zaulere, chonde funsani ngati pali malonda.

Q: Kodi mungapereke zinthu zomwe zikugwirizana ndi NACE?

A: Inde, tingathe.

Zipangizo zolumikizira mapaipi ndi zinthu zofunika kwambiri mu dongosolo la mapaipi, zomwe zimagwiritsidwa ntchito polumikiza, kusinthira, kusintha kukula, kutseka kapena kuwongolera kayendedwe ka madzi. Zimagwiritsidwa ntchito kwambiri m'magawo monga zomangamanga, mafakitale, mphamvu ndi ntchito za m'matauni.

Ntchito Zofunika Kwambiri:Imatha kugwira ntchito monga kulumikiza mapaipi, kusintha njira yoyendera, kugawa ndi kuphatikiza madzi oyenda, kusintha mainchesi a mapaipi, kutseka mapaipi, kuwongolera ndikuwongolera.

Chiwerengero cha Ntchito:

- Kupereka madzi ndi ngalande m'nyumba:Zigongono za PVC ndi ma PPR tris amagwiritsidwa ntchito pa maukonde a mapaipi amadzi.

- Mapaipi a mafakitale:Ma flange achitsulo chosapanga dzimbiri ndi zigongono zachitsulo chopangidwa ndi alloy zimagwiritsidwa ntchito kunyamula zinthu zamagetsi.

- Kuyendera mphamvu:Mapaipi achitsulo amphamvu kwambiri amagwiritsidwa ntchito m'mapaipi amafuta ndi gasi.

- HVAC (Kutenthetsa, Kupumira mpweya, ndi Kuziziritsa Mpweya):Zipangizo za mapaipi a mkuwa zimagwiritsidwa ntchito polumikiza mapaipi oziziritsa, ndipo malo olumikizirana osinthasintha amagwiritsidwa ntchito pochepetsa kugwedezeka.

- Ulimi wothirira:Zolumikizira mwachangu zimathandiza kusonkhanitsa ndi kusokoneza makina othirira opopera madzi.