MFUNDO

| Dzina lazogulitsa | socket weld flange |

| Kukula | 1/2"-24" |

| Kupanikizika | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5, EN1092-1, JIS B2220 etc. |

| Khoma makulidwe | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS ndi zina. |

| Zakuthupi | Chitsulo chosapanga dzimbiri:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1,4347, 1,4347 1.4571,1.4541, 254Mo ndi zina. |

| Chitsulo cha carbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Chitsulo chosapanga dzimbiri cha Duplex:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 ndi zina. | |

| Chitsulo cha bomba:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo aloyi:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Kugwiritsa ntchito | Makampani a petrochemical;makampani opanga ndege ndi zakuthambo; makampani opanga mankhwala; utsi wa gasi; malo opangira magetsi; zomangamanga; kukonza madzi, etc. |

| Ubwino wake | katundu wokonzeka, nthawi yobweretsera mwachangu; kupezeka mumitundu yonse, makonda;pamwamba kwambiri |

DIMENSION STUDY

PRODUCTS DETAIL SHOW

1. Nkhope

Itha kukwezedwa nkhope (RF), nkhope yonse (FF), mphete ya mphete (RTJ), Groove, Lilime, kapena makonda.

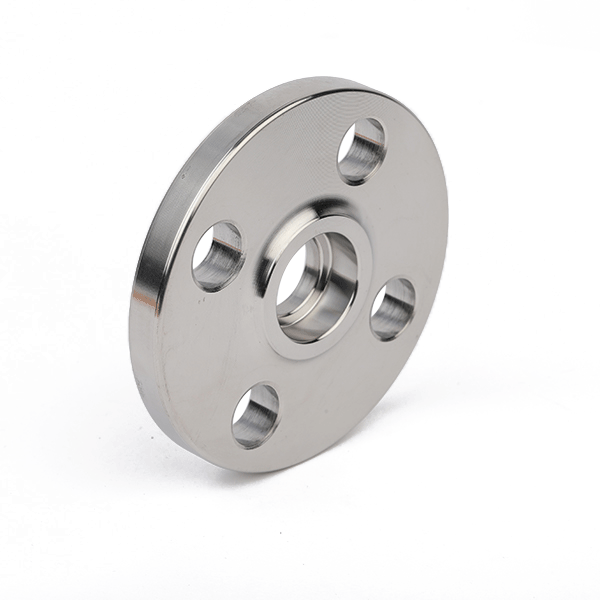

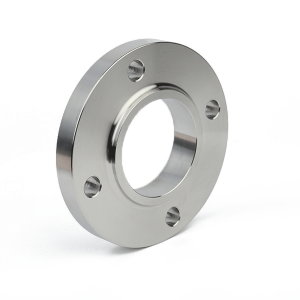

2.Socket weld

3.CNC chabwino anamaliza

Kumaliza kumaso: Kumaliza kumaso kwa flange kumayesedwa ngati Arithmetical Average Roughness Height(AARH). Kumaliza kumatsimikiziridwa ndi muyezo womwe umagwiritsidwa ntchito. Mwachitsanzo, ANSI B16.5 imatchula mapeto a nkhope mkati mwa 125AARH-500AARH (3.2Ra mpaka 12.5Ra). Zomaliza zina zilipo pa pempho, mwachitsanzo 1.6 Ra max, 1.6 / 3.2 Ra, 3.2 / 6.3Ra kapena 6.3 / 12.5Ra. Mtundu wa 3.2 / 6.3Ra ndiwofala kwambiri.

KUSINTHA NDI KUPAKA

• Chigawo chilichonse chimagwiritsa ntchito filimu yapulasitiki kuteteza pamwamba

• Pazitsulo zonse zosapanga dzimbiri zimadzaza ndi plywood case. Kwa kukula kwakukulu kwa kaboni flange amadzazidwa ndi plywood pallet. Kapena akhoza makonda kulongedza katundu.

• Kutumiza chizindikiro kungapange pa pempho

• Zolemba pazogulitsa zimatha kujambulidwa kapena kusindikizidwa. OEM amavomerezedwa.

KUYENDERA

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Dimension test

Asanaperekedwe, gulu lathu la QC lidzakonza mayeso a NDT ndi kuyezetsa mawonekedwe. Komanso kuvomereza TPI (kuwunika kwa gulu lachitatu).

NJIRA YOPHUNZITSA

| 1. Sankhani Genuine yaiwisi | 2. Dulani zopangira | 3. Pre-kutentha |

| 4. Kunyenga | 5. Chithandizo cha kutentha | 6. Makina Ovuta |

| 7. Kubowola | 8. Kuchita bwino | 9. Kulemba chizindikiro |

| 10. Kuyendera | 11. Kunyamula | 12. Kutumiza |

FAQ

1. Kodi ANSI B16.5 yopangira zitsulo zosapanga dzimbiri weld flange ndi chiyani?

ANSI B16.5 Forged Stainless Steel Socket Weld Flange ndi flange yomwe imagwiritsidwa ntchito kujowina mapaipi pakugwiritsa ntchito kuthamanga kwambiri. Amapangidwa ndi chitsulo chosapanga dzimbiri chopangidwa ndi ma socket weld kuti akhazikike mosavuta.

2. Kodi ma flange a ANSI B16.5 opangira zitsulo zosapanga dzimbiri amasiyana bwanji ndi mitundu ina ya flange?

Mosiyana ndi mitundu ina ya flange, ANSI B16.5 yopangira zitsulo zosapanga dzimbiri zowotcherera zitsulo zimafunikira kulumikizana kwa socket weld komwe chitoliro chimayikidwa mu flange ndikuwotcherera mkati. Izi zimapereka mgwirizano wamphamvu komanso wosadukiza.

3. Ubwino wogwiritsa ntchito ANSI B16.5 ndi zitsulo zosapanga dzimbiri zopangira socket weld flanges ndi ziti?

Zopindulitsa zazikulu zogwiritsira ntchito ANSI B16.5 zopangira zitsulo zosapanga dzimbiri zowotcherera zimaphatikizanso mphamvu zambiri, kudalirika komanso kukana kwa dzimbiri. Ndi abwino kwa ntchito zomwe zimafuna zolimba, zotetezeka.

4. Ndi mafakitale ati omwe amakonda kugwiritsa ntchito ANSI B16.5 zitsulo zopangira zitsulo zosapanga dzimbiri?

ANSI B16.5 yopangira zitsulo zosapanga dzimbiri zowotcherera zitsulo zimagwiritsidwa ntchito kwambiri m'mafakitale amafuta ndi gasi, petrochemical, mankhwala, opanga magetsi ndi mafakitale opangira madzi. Iwo ali oyenerera kupanikizika kwakukulu ndi ntchito zotentha kwambiri.

5. Kodi ANSI B16.5 zopanga zitsulo zosapanga dzimbiri weld flanges ntchito gasi ndi madzi ntchito?

Inde, ma ANSI B16.5 opangira zitsulo zosapanga dzimbiri weld flanges amapezeka kuti agwiritse ntchito gasi ndi madzi. Zapangidwa kuti zipereke mgwirizano wotetezeka ndipo zimatha kupirira kupanikizika ndi kutentha kwa madzi ambiri.

6. Ndimiyezo yotani yomwe imatsatiridwa popanga ma flanges a ANSI B16.5 opangira zitsulo zosapanga dzimbiri?

ANSI B16.5 Forged Stainless Steel Socket Weld Flanges amapangidwa motsatira miyezo yokhazikitsidwa ndi American National Standards Institute (ANSI). Miyezo iyi imatsimikizira kuti ma flanges amakwaniritsa zofunikira komanso magwiridwe antchito.

7. Kodi ANSI B16.5 zopanga zitsulo zosapanga dzimbiri weld flanges zilipo mu makulidwe osiyanasiyana ndi kukakamiza?

Inde, ma ANSI B16.5 opangira zitsulo zosapanga dzimbiri weld flanges amapezeka mosiyanasiyana komanso kukakamiza. Izi zimathandiza kusinthasintha ndi kuyanjana ndi machitidwe osiyanasiyana a mapaipi ndi zofunikira.

8. Kodi ANSI B16.5 zitsulo zopanga zitsulo zosapanga dzimbiri zowotcherera zitha kugwiritsidwa ntchito polumikizana ndi kukwezeka ndi kumtunda?

Inde, ma ANSI B16.5 opangira zitsulo zosapanga dzimbiri weld flanges amapezeka pazolumikizana zonse zokwezeka kumaso ndi kumaso. Nkhope za Flange zitha kusinthidwa kuti zikwaniritse zosowa za pulogalamuyo.

9. Kodi ANSI B16.5 zopangira zitsulo zosapanga dzimbiri weld flanges ndizoyenera kugwiritsa ntchito kutentha kwambiri?

Inde, ANSI B16.5 zopangira zitsulo zosapanga dzimbiri weld flanges ndizoyenera kugwiritsa ntchito kutentha kwambiri. Amapangidwa kuti azipirira kutentha kwambiri popanda kusokoneza kukhulupirika kwawo.

10. Kodi ANSI B16.5 yopangira zitsulo zosapanga dzimbiri weld flanges iyenera kukhazikitsidwa bwanji?

ANSI B16.5 Zopangira zitsulo zosapanga dzimbiri zowotcherera zidzayikidwa m'njira yoti chitolirocho chilowetsedwe mu socket weld ndikumangirira mkati. Ndikofunika kuonetsetsa kuti kuwotcherera koyenera kumatheka kuti mukhalebe ndi mphamvu ndi kukhulupirika kwa mgwirizano.

Zogulitsa zikuwonetsa

1. Nkhope

Itha kukwezedwa nkhope (RF), nkhope yonse (FF), mphete ya mphete (RTJ), Groove, Lilime, kapena makonda.

2.Socket weld

3.CNC chabwino anamaliza

Kumaliza kumaso: Kumaliza kumaso kwa flange kumayesedwa ngati Arithmetical Average Roughness Height(AARH). Kumaliza kumatsimikiziridwa ndi muyezo womwe umagwiritsidwa ntchito. Mwachitsanzo, ANSI B16.5 imatchula mapeto a nkhope mkati mwa 125AARH-500AARH (3.2Ra mpaka 12.5Ra). Zomaliza zina zilipo pa pempho, mwachitsanzo 1.6 Ra max, 1.6 / 3.2 Ra, 3.2 / 6.3Ra kapena 6.3 / 12.5Ra. Mtundu wa 3.2 / 6.3Ra ndiwofala kwambiri.

Kulemba ndi Kupakira

• Chigawo chilichonse chimagwiritsa ntchito filimu yapulasitiki kuteteza pamwamba

• Pazitsulo zonse zosapanga dzimbiri zimadzaza ndi plywood case. Kwa kukula kwakukulu kwa kaboni flange amadzazidwa ndi plywood pallet. Kapena akhoza makonda kulongedza katundu.

• Kutumiza chizindikiro kungapange pa pempho

• Zolemba pazogulitsa zimatha kujambulidwa kapena kusindikizidwa. OEM amavomerezedwa.

Kuyendera

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Dimension test

Asanaperekedwe, gulu lathu la QC lidzakonza mayeso a NDT ndi kuyezetsa mawonekedwe. Komanso kuvomereza TPI (kuwunika kwa gulu lachitatu).

Njira yopanga

| 1. Sankhani Genuine yaiwisi | 2. Dulani zopangira | 3. Pre-kutentha |

| 4. Kunyenga | 5. Chithandizo cha kutentha | 6. Makina Ovuta |

| 7. Kubowola | 8. Kuchita bwino | 9. Kulemba chizindikiro |

| 10. Kuyendera | 11. Kunyamula | 12. Kutumiza |

-

ASME B16.5 BL RF ASTM A182 F316L Zosapanga dzimbiri ...

-

Masinthidwe Osasinthika a Tube Mapepala a Flange...

-

adapanga asme b16.36 wn orifice flange ndi Jack ...

-

AMSE B16.5 A105 kaboni zitsulo weld khosi f ...

-

ASTM A182 F51 F53 BL ANSI B16.5 Chitsulo chosapanga dzimbiri...

-

ANSI DIN Forged Class150 Slipless Steel Slip o...