ZOKHUDZA

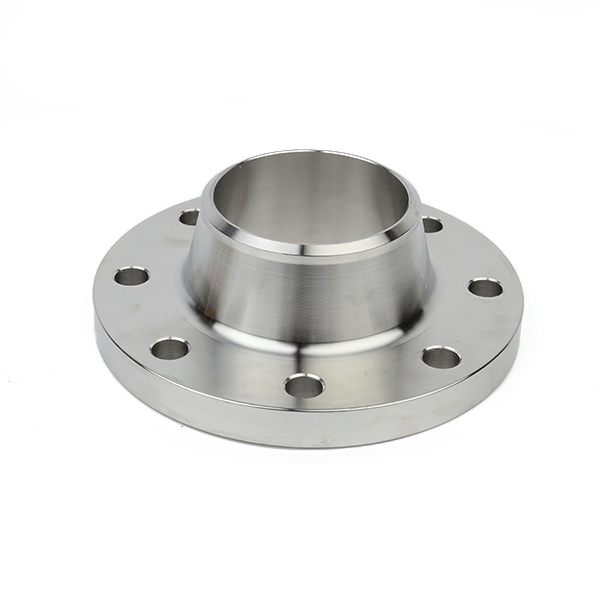

| Dzina la Chinthu | Chingwe cholumikizira/Flange yotayirira |

| Kukula | 1/2"-24" |

| Kupanikizika | 150#-2500#,PN0.6-PN400,5K-40K |

| Muyezo | ANSI B16.5, EN1092-1, JIS B2220 etc. |

| Mapeto a stub | MSS SP 43, ASME B16.9 |

| Zinthu Zofunika | Chitsulo chosapanga dzimbiri:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo ndi zina zotero. |

| Chitsulo cha kaboni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 ndi zina zotero. | |

| Chitsulo chosapanga dzimbiri:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 ndi zina zotero. | |

| Chitsulo cha payipi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 ndi zina zotero. | |

| Aloyi wa nikeli:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 ndi zina zotero. | |

| Cr-Mo aloyi:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, ndi zina zotero. | |

| Kugwiritsa ntchito | Makampani opanga mafuta; makampani opanga ndege ndi ndege; makampani opanga mankhwala; utsi wa gasi; malo opangira magetsi; nyumba yomanga sitima; kukonza madzi, ndi zina zotero. |

| Ubwino | katundu wokonzeka, nthawi yotumizira mwachangu; imapezeka mumitundu yonse, yosinthidwa; yapamwamba kwambiri |

MIYEZO YA DIMENSION

ZOCHITIKA ZAMBIRI ZOGWIRITSA NTCHITO CHIWONETSERO

1. Nkhope

Ikhoza kukwezedwa nkhope (RF), nkhope yonse (FF), mphete yolumikizira (RTJ), Groove, Lilime, kapena yosinthidwa.

2. Mapeto a Bevel malinga ndi ANSI B16.25

3.CNC fine yatha.

Kumaliza kwa nkhope: Kumaliza kwa nkhope ya flange kumayesedwa ngati Kutalika kwa Avereji ya Kuuma kwa Arithmetical (AARH). Kumaliza kumatsimikiziridwa ndi muyezo womwe umagwiritsidwa ntchito. Mwachitsanzo, ANSI B16.5 imatchula kumaliza kwa nkhope mkati mwa 125AARH-500AARH (3.2Ra mpaka 12.5Ra). Kumaliza kwina kumapezeka pa requst, mwachitsanzo 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra kapena 6.3/12.5Ra. Kutalikirana kwa 3.2/6.3Ra ndikofala kwambiri.

KULEMBA NDI KUPAKIRA

• Gawo lililonse ligwiritse ntchito filimu ya pulasitiki kuti liteteze pamwamba pake

• Pazitsulo zonse zosapanga dzimbiri, zimayikidwa ndi bokosi la plywood. Kuti flange ya carbon ikhale yayikulu, imayikidwa ndi plywood pallet. Kapena ikhoza kukonzedwa mwamakonda.

• Chizindikiro chotumizira chingapangidwe ngati pakufunika

• Zolemba pa zinthu zitha kujambulidwa kapena kusindikizidwa. OEM yalandiridwa.

KUYENDA

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Kuyesa kukula

Gulu lathu la QC lidzakonza mayeso a NDT ndikuwunika kukula kwake. Lidzavomerezanso TPI (kuyang'aniridwa ndi chipani chachitatu).

NJIRA YOPANGIDWA

| 1. Sankhani zinthu zenizeni zopangira | 2. Dulani zinthu zopangira | 3. Kutentha koyambirira |

| 4. Kupangira | 5. Kuchiza kutentha | 6. Makina Ovuta |

| 7. Kuboola | 8. Kukonza bwino | 9. Kulemba |

| 10. Kuyendera | 11. Kulongedza | 12. Kutumiza |

Mlanduwu wa mgwirizano

Pulojekiti ku Turkey, ma flange amagwiritsidwa ntchito m'mapaipi a gasi lachilengedwe. Ma flange onsewo avomerezedwa ndi TUV.

TSAMBA LA DATA LA FLANGE

1Miyeso ya flange ndi kulekerera kwake ziyenera kukhala molingana ndi ASME B16.5.

2. Ma flange ayenera kupangidwa pogwiritsa ntchito forging.

3. Zipangizo ziyenera kukhala motsatira miyezo ya ASTM A105, ASTM A694 F65 ndi ASTM A694 F70.

4. Ma flange a ASTM A694 F65 ndi ASTM A694 F70 ayenera kuzimitsidwa ndi kutenthedwa.

5. Zikalata zoyesera zinthu ndi malipoti ochizira kutentha ziyenera kupezeka kuti ziwunikidwe ndi TPI.

6. Ma flange a WN ayenera kukhala ndi ma bevel end acc. ku ASME B16.25.

7. Zipangizo zoyesera mankhwala ndi makina (mphamvu, phindu, kukakamiza ndi zina zotero) ziyenera kukhala motsatira miyezo yofananira.

8. Malo onse ayenera kupakidwa ndi makina ndi vanishi ndi mafuta owonekera bwino kuti asachite dzimbiri.

9. Kulemba kuyenera kuphatikizapo mfundo zotsatirazi,

• M'mimba mwake (kutha kwa 6”)

• Kalasi ya kupanikizika (yotha ntchito 150 LB)

• Kalasi ya Zinthu (yomaliza ntchito ya ASTM A 105)

• Kukhuthala kwa khoma (mpaka 4,78 mm)

• Nambala ya Kutentha (yotha ntchito 138413)

• Muyezo wa kupanga (ASME B16.5)

10. Zipangizo ziyenera kukhala zopanda vuto lililonse pamwamba ndi ming'alu. Kukonza zowotcherera n'koletsedwa mwamphamvu.

11. Ma flange onse ayenera kukhala ndi nkhope yokwezedwa (RF) yokhala ndi malo otsekera. Malo otsekera ayenera kukhala Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. ku ASME B46.1.

12. Zipangizo ziyenera kupakidwa kuti zisawonongeke pamakina, ndi kutseka malo.

13. Miyeso yonse ikhale ndi ma tolerance abwino (+). Ma tolerance ochepa ndi oletsedwa mwamphamvu.

14. Ma bevelings a flange ayenera kulumikizidwa ku ASME B16.25.

15. Njira yopangira idzayang'aniridwa nthawi iliyonse ndi TPI.

16. TPI ikhoza kutenga zitsanzo kuchokera ku chinthu chilichonse choyesera mankhwala/makina.

17. Lipoti lolowera loyang'anira lidzawunikidwanso ndi TPI.

| Chinthu | Kukula (Inchi) | Kalasi Yopanikizika | CS | Zinthu Zofunika | Kulemera (mm) | Malo | Kuchuluka. |

| SORF | 12 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 32 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 14 | MALANGIZO A THANK | 2 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 5.54 | MALANGIZO A THANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 6 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 5.54 | MALANGIZO A THANK | 8 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 14 | MALANGIZO A THANK | 8 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 16 | MALANGIZO A THANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 6 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 5.54 | MALANGIZO A THANK | 8 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 14 | MALANGIZO A THANK | 16 |

| Chinthu | Kukula (Inchi) | Kalasi Yopanikizika | CS | Zinthu Zofunika | Kulemera (mm) | Malo | Kuchuluka. |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Khosi Lopindika | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Khosi Lopindika | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Khosi Lopindika | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Khosi Lopindika | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Khosi Lopindika | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Khosi Lopindika | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Khosi Lopindika | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Khosi Lopindika | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Khosi Lopindika | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Khosi Lopindika | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Khosi Lopindika | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

FAQ

1. Kodi mitundu yosiyanasiyana ya zipangizo zopangira mapaipi achitsulo chosapanga dzimbiri ndi iti?

Yankho: Zolumikizira mapaipi zosapanga dzimbiri zimaphatikizapo zolumikizira mapaipi zolumikizira matako, zolumikizira mapaipi zolumikizira soketi, zolumikizira mapaipi zolumikizidwa, ma flange, ma valve ndi mitundu ina.

2. Kodi kusiyana pakati pa zipangizo zolumikizira mapaipi a chitsulo chosapanga dzimbiri 304 ndi 316 ndi kotani?

A: Chitsulo chosapanga dzimbiri cha 304 ndi choyenera kugwiritsidwa ntchito kwambiri ndipo chili ndi kukana dzimbiri kwabwino. Koma chitsulo chosapanga dzimbiri cha 316, chili ndi kukana dzimbiri kwabwino m'malo owononga kwambiri ndipo chimagwiritsidwa ntchito bwino m'madzi ndi m'mankhwala.

3. Kodi ubwino wogwiritsa ntchito zida zolumikizira mapaipi zolumikizidwa ndi forged butt ndi wotani?

A: Zolumikizira zolumikizira matako zopangidwa ndi chitsulo cholimba zimapereka mphamvu yowonjezera, kudalirika, komanso kulumikizana kosataya madzi. Zimapereka kukana kwabwino kwambiri ndipo zimakondedwa kwambiri pakugwiritsa ntchito mphamvu yamagetsi komanso kutentha kwambiri.

4. Kodi flange yolumikizira matako ndi chiyani?

Yankho: Flange yolumikizira matako ndi flange ya paipi yomwe ili ndi hub yayitali yopapatiza ndipo imalumikizidwa ku payipi. Imapereka kusintha kosalala kuchokera ku payipi kupita ku flange ndi mphamvu yabwino komanso umphumphu.

5. Ndi mtundu uti wa chitsulo chosapanga dzimbiri womwe umagwiritsidwa ntchito kwambiri popangira mapaipi?

A: Magiredi a chitsulo chosapanga dzimbiri 304, 316, 304L, 316L ndi 317 amagwiritsidwa ntchito kwambiri mu zolumikizira mapaipi chifukwa cha kukana dzimbiri, kulimba komanso kusinthasintha kwawo.

6. Kodi zipangizo zopangira mapaipi achitsulo chosapanga dzimbiri zingagwiritsidwe ntchito pa kutentha kwambiri?

Yankho: Inde, zomangira zachitsulo chosapanga dzimbiri ndizoyenera kugwiritsidwa ntchito kutentha kwambiri. Komabe, mtundu wa chitsulo chosapanga dzimbiri chomwe chimagwiritsidwa ntchito uyenera kusankhidwa mosamala kutengera zomwe zimafunika kutentha kwa chipangizocho.

7. Kodi zipangizo zopangira mapaipi achitsulo chosapanga dzimbiri ndizoyenera makampani opanga chakudya ndi zakumwa?

Yankho: Inde, zolumikizira zachitsulo chosapanga dzimbiri zimagwiritsidwa ntchito kwambiri mumakampani azakudya ndi zakumwa chifukwa cha ukhondo wawo, kukana dzimbiri, komanso kusamalira mosavuta.

8. Kodi kusiyana pakati pa zolumikizira zolumikizira za socket ndi zolumikizira za butt welding ndi kotani?

Yankho: Zolumikizira mapaipi zolumikizidwa ndi soketi zimalowetsa chitolirocho mu soketi kenako n’kulumikiza fillet kuti chitolirocho chilumikizidwe. Zolumikizira za butt weld, kumbali ina, zimafuna kuti malekezero a chitolirocho apangidwe beveled kenako apangidwe.

9. Kodi zolumikizira za mapaipi achitsulo chosapanga dzimbiri zingabwezeretsedwenso?

A: Inde, zolumikizira zachitsulo chosapanga dzimbiri zimatha kubwezeretsedwanso. Chitsulo chosapanga dzimbiri ndi chinthu chokhazikika chomwe chingabwezeretsedwenso ndikugwiritsidwanso ntchito popanda kutaya makhalidwe ake kapena khalidwe lake.

10. Kodi ubwino wogwiritsa ntchito zipangizo zoyezera mapaipi achitsulo chosapanga dzimbiri ndi wotani poyerekeza ndi zipangizo zina?

A: Zolumikizira mapaipi zosapanga dzimbiri zimapereka zabwino zambiri, monga kukana dzimbiri bwino, mphamvu zambiri, kulimba komanso makhalidwe aukhondo. Sizimasamalidwa bwino, zimakhala ndi moyo wautali komanso zimakhala zoyera komanso zokongola.

ZOCHITIKA ZAMBIRI ZOGWIRITSA NTCHITO CHIWONETSERO

1. Nkhope

Ikhoza kukwezedwa nkhope (RF), nkhope yonse (FF), mphete yolumikizira (RTJ), Groove, Lilime, kapena yosinthidwa.

2. Mapeto a Bevel malinga ndi ANSI B16.25

3.CNC fine yatha.

Kumaliza kwa nkhope: Kumaliza kwa nkhope ya flange kumayesedwa ngati Kutalika kwa Avereji ya Kuuma kwa Arithmetical (AARH). Kumaliza kumatsimikiziridwa ndi muyezo womwe umagwiritsidwa ntchito. Mwachitsanzo, ANSI B16.5 imatchula kumaliza kwa nkhope mkati mwa 125AARH-500AARH (3.2Ra mpaka 12.5Ra). Kumaliza kwina kumapezeka pa requst, mwachitsanzo 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra kapena 6.3/12.5Ra. Kutalikirana kwa 3.2/6.3Ra ndikofala kwambiri.

KULEMBA NDI KUPAKIRA

• Gawo lililonse ligwiritse ntchito filimu ya pulasitiki kuti liteteze pamwamba pake

• Pazitsulo zonse zosapanga dzimbiri, zimayikidwa ndi bokosi la plywood. Kuti flange ya carbon ikhale yayikulu, imayikidwa ndi plywood pallet. Kapena ikhoza kukonzedwa mwamakonda.

• Chizindikiro chotumizira chingapangidwe ngati pakufunika

• Zolemba pa zinthu zitha kujambulidwa kapena kusindikizidwa. OEM yalandiridwa.

KUYENDA

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Kuyesa kukula

Gulu lathu la QC lidzakonza mayeso a NDT ndikuwunika kukula kwake. Lidzavomerezanso TPI (kuyang'aniridwa ndi chipani chachitatu).

NJIRA YOPANGIDWA

| 1. Sankhani zinthu zenizeni zopangira | 2. Dulani zinthu zopangira | 3. Kutentha koyambirira |

| 4. Kupangira | 5. Kuchiza kutentha | 6. Makina Ovuta |

| 7. Kuboola | 8. Kukonza bwino | 9. Kulemba |

| 10. Kuyendera | 11. Kulongedza | 12. Kutumiza |

Mlanduwu wa mgwirizano

Pulojekiti ku Turkey, ma flange amagwiritsidwa ntchito m'mapaipi a gasi lachilengedwe. Ma flange onsewo avomerezedwa ndi TUV.

TSAMBA LA DATA LA FLANGE

1. Miyeso ndi kulekerera kwa flange ziyenera kukhala molingana ndi ASME B16.5.

2. Ma flange ayenera kupangidwa pogwiritsa ntchito forging.

3. Zipangizo ziyenera kukhala motsatira miyezo ya ASTM A105, ASTM A694 F65 ndi ASTM A694 F70.

4. Ma flange a ASTM A694 F65 ndi ASTM A694 F70 ayenera kuzimitsidwa ndi kutenthedwa.

5. Zikalata zoyesera zinthu ndi malipoti ochizira kutentha ziyenera kupezeka kuti ziwunikidwe ndi TPI.

6. Ma flange a WN ayenera kukhala ndi ma bevel end acc. ku ASME B16.25.

7. Zipangizo zoyesera mankhwala ndi makina (mphamvu, phindu, kukakamiza ndi zina zotero) ziyenera kukhala motsatira miyezo yofananira.

8. Malo onse ayenera kupakidwa ndi makina ndi vanishi ndi mafuta owonekera bwino kuti asachite dzimbiri.

9. Kulemba kuyenera kuphatikizapo mfundo zotsatirazi,

• M'mimba mwake (kutha kwa 6”)

• Kalasi ya kupanikizika (yotha ntchito 150 LB)

• Kalasi ya Zinthu (yomaliza ntchito ya ASTM A 105)

• Kukhuthala kwa khoma (mpaka 4,78 mm)

• Nambala ya Kutentha (yotha ntchito 138413)

• Muyezo wa kupanga (ASME B16.5)

10. Zipangizo ziyenera kukhala zopanda vuto lililonse pamwamba ndi ming'alu. Kukonza zowotcherera n'koletsedwa mwamphamvu.

11. Ma flange onse ayenera kukhala ndi nkhope yokwezedwa (RF) yokhala ndi malo otsekera. Malo otsekera ayenera kukhala Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. ku ASME B46.1.

12. Zipangizo ziyenera kupakidwa kuti zisawonongeke pamakina, ndi kutseka malo.

13. Miyeso yonse ikhale ndi ma tolerance abwino (+). Ma tolerance ochepa ndi oletsedwa mwamphamvu.

14. Ma bevelings a flange ayenera kulumikizidwa ku ASME B16.25.

15. Njira yopangira idzayang'aniridwa nthawi iliyonse ndi TPI.

16. TPI ikhoza kutenga zitsanzo kuchokera ku chinthu chilichonse choyesera mankhwala/makina.

17. Lipoti lolowera loyang'anira lidzawunikidwanso ndi TPI.

| Chinthu | Kukula (Inchi) | Kalasi Yopanikizika | CS | Zinthu Zofunika | Kulemera (mm) | Malo | Kuchuluka. |

| SORF | 12 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 32 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 14 | MALANGIZO A THANK | 2 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 5.54 | MALANGIZO A THANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 6 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 5.54 | MALANGIZO A THANK | 8 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 14 | MALANGIZO A THANK | 8 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 16 | MALANGIZO A THANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | MALANGIZO A THANK | 6 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 5.54 | MALANGIZO A THANK | 8 |

| Flange, Khosi Lopindika | 24 | 150LB | 20 | A105 | 14 | MALANGIZO A THANK | 16 |

| Chinthu | Kukula (Inchi) | Kalasi Yopanikizika | CS | Zinthu Zofunika | Kulemera (mm) | Malo | Kuchuluka. |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Khosi Lopindika | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Khosi Lopindika | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Khosi Lopindika | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Khosi Lopindika | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Khosi Lopindika | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Khosi Lopindika | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Khosi Lopindika | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Khosi Lopindika | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Khosi Lopindika | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Khosi Lopindika | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Khosi Lopindika | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Khosi Lopindika | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Khosi Lopindika | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Zipangizo zolumikizira mapaipi ndi zinthu zofunika kwambiri mu dongosolo la mapaipi, zomwe zimagwiritsidwa ntchito polumikiza, kusinthira, kusintha kukula, kutseka kapena kuwongolera kayendedwe ka madzi. Zimagwiritsidwa ntchito kwambiri m'magawo monga zomangamanga, mafakitale, mphamvu ndi ntchito za m'matauni.

Ntchito Zofunika Kwambiri:Imatha kugwira ntchito monga kulumikiza mapaipi, kusintha njira yoyendera, kugawa ndi kuphatikiza madzi oyenda, kusintha mainchesi a mapaipi, kutseka mapaipi, kuwongolera ndikuwongolera.

Chiwerengero cha Ntchito:

- Kupereka madzi ndi ngalande m'nyumba:Zigongono za PVC ndi ma PPR tris amagwiritsidwa ntchito pa maukonde a mapaipi amadzi.

- Mapaipi a mafakitale:Ma flange achitsulo chosapanga dzimbiri ndi zigongono zachitsulo chopangidwa ndi alloy zimagwiritsidwa ntchito kunyamula zinthu zamagetsi.

- Kuyendera mphamvu:Mapaipi achitsulo amphamvu kwambiri amagwiritsidwa ntchito m'mapaipi amafuta ndi gasi.

- HVAC (Kutenthetsa, Kupumira mpweya, ndi Kuziziritsa Mpweya):Zipangizo za mapaipi a mkuwa zimagwiritsidwa ntchito polumikiza mapaipi oziziritsa, ndipo malo olumikizirana osinthasintha amagwiritsidwa ntchito pochepetsa kugwedezeka.

- Ulimi wothirira:Zolumikizira mwachangu zimathandiza kusonkhanitsa ndi kusokoneza makina othirira opopera madzi.

-

Zopangira chitoliro A105 Class 150 Ss Carbon Steel Pl ...

-

Chitsulo Cholimba Cholimba Cholimba Cholimba ...

-

chitsulo cha kaboni chotulutsa khosi mtundu wa 6″ ANSI CLASS ...

-

chitsulo cha kaboni a105 forge blind BL flange

-

Chitsulo chosapanga dzimbiri cha ASTM A182 F51 F53 BL ANSI B16.5 ...

-

Flange ya orifice WN 4″ 900# RF A105 dual gr ...