MFUNDO

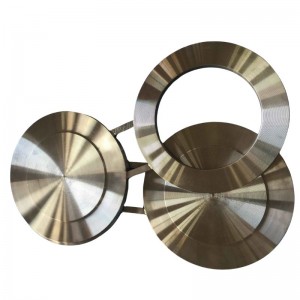

| Dzina lazogulitsa | Chipinda cholumikizira / Lose flange |

| Kukula | 1/2"-24" |

| Kupanikizika | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5, EN1092-1, JIS B2220 etc. |

| Mapeto a stub | MSS SP 43, ASME B16.9 |

| Zakuthupi | Chitsulo chosapanga dzimbiri:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1,4347, 1,4347 1.4571,1.4541, 254Mo ndi zina. |

| Chitsulo cha carbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Chitsulo chosapanga dzimbiri cha Duplex:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 ndi zina. | |

| Chitsulo cha bomba:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo aloyi:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Kugwiritsa ntchito | Makampani a petrochemical;makampani opanga ndege ndi zakuthambo; makampani opanga mankhwala; utsi wa gasi; malo opangira magetsi; zomangamanga; kukonza madzi, etc. |

| Ubwino wake | katundu wokonzeka, nthawi yobweretsera mwachangu; kupezeka mumitundu yonse, makonda;pamwamba kwambiri |

DIMENSION STUDY

LAP JOINT FLANGE

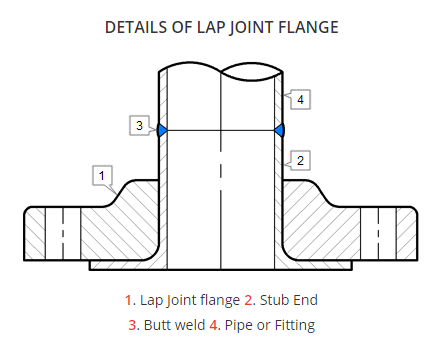

Flange yolumikizana ndi lap imafuna zigawo ziwiri za mapaipi kumbali iliyonse ya cholumikizira cholumikizira, chomangira chamkati ndi cholumikizira chokhazikika. Flange yotayirira imafika pamtunda wakunja kwa nsonga, yomwe imakhala yomangika pamapaipi. The flange kumbuyo si welded ku chitoliro, ndipo amatha kusinthasintha, zomwe zimakhala zothandiza makamaka pakufunika kuwongolera ma flanges panthawi yomanga.

Komanso, monga flange kumbuyo sichimakhudzana ndi njira yamadzimadzi, imatha kupangidwa ndi zinthu zochepa zosawononga. Mwachitsanzo, ngati ndondomekoyi ikuwononga ndipo imafuna kuti chitolirocho chikhale chachitsulo chosapanga dzimbiri, monga ASTM A312 TP316L, ndiye kuti mapeto a stub ayeneranso kupangidwa ndi SS 316L; komabe, flange yochirikiza imatha kupangidwa ndi mtengo wotsika mtengo wa ASTM A105.

Njira yolumikizirana iyi si yolimba ngati khosi la weld flange koma ndiyabwino kuposa zomata, socket weld, ndi slip pa zolumikizira; komabe, ndi okwera mtengo kwambiri kuti aphedwe, chifukwa pamafunika kuwotcherera kwathunthu koma kumafuna zigawo ziwiri.

STUB MAPETO

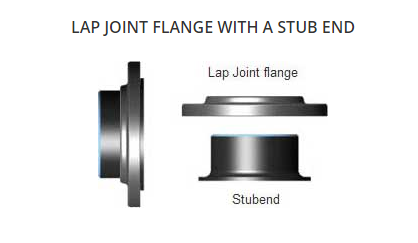

Mapeto a Stub nthawi zonse adzagwiritsidwa ntchito ndi Lap Joint flange, ngati flange yothandizira.

Malumikizidwe a flangewa amagwiritsidwa ntchito, m'machitidwe otsika komanso osafunikira, ndipo ndi njira yotsika mtengo yopangira.

Mu dongosolo lazitsulo zosapanga dzimbiri, mwachitsanzo, chitsulo cha carbon steel flange chingagwiritsidwe ntchito, chifukwa sichimakhudzana ndi mankhwala mu chitoliro.

Ma Stub End amapezeka pafupifupi ma diameter onse a chitoliro. Makulidwe ndi kulolerana kwamitundu kumatanthauzidwa mu ASME B.16.9 muyezo. Ma Stub Ends (zowonjezera) zosagwirizana ndi kuwala kwa corrosion amatanthauzidwa mu MSS SP43.

ZOTHANDIZA KWA LAP JOINT FLANGE

- Ufulu woyendayenda mozungulira chitoliro umathandizira kulumikiza mabowo a flange otsutsana.

- Kupanda kukhudzana ndi madzimadzi mu chitoliro nthawi zambiri amalola ntchito yotsika mtengo mpweya zitsulo flanges ndi dzimbiri kugonjetsedwa chitoliro.

- M'makina omwe amakokoloka kapena kuwononga mwachangu, ma flanges amatha kupulumutsidwa kuti agwiritsidwenso ntchito.

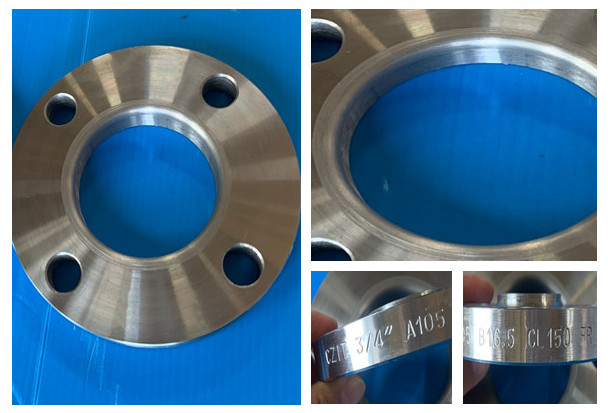

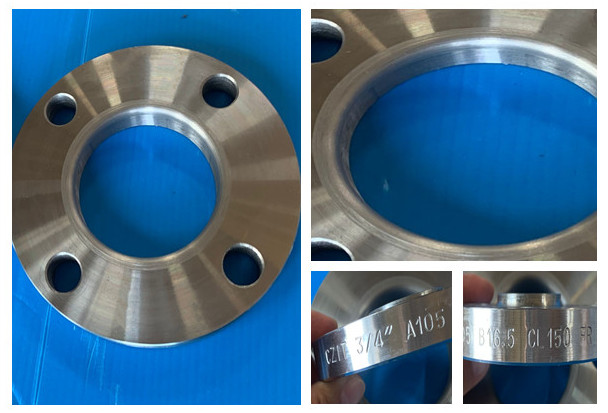

PRODUCTS DETAIL SHOW

1. Nkhope

nkhope yosalala, Radius ndiye yofunika kwambiri

2. Ndi likulu kapena opanda likulu

3.Kumaliza kwa nkhope

Mapeto pa nkhope ya flange amayezedwa ngati Arithmetical Average Roughness Height(AARH). Kumaliza kumatsimikiziridwa ndi muyezo womwe umagwiritsidwa ntchito. Mwachitsanzo, ANSI B16.5 imatchula mapeto a nkhope mkati mwa 125AARH-500AARH (3.2Ra mpaka 12.5Ra). Zomaliza zina zilipo pa pempho, mwachitsanzo 1.6 Ra max, 1.6 / 3.2 Ra, 3.2 / 6.3Ra kapena 6.3 / 12.5Ra. Mtundu wa 3.2 / 6.3Ra ndiwofala kwambiri.

KUSINTHA NDI KUPAKA

• Chigawo chilichonse chimagwiritsa ntchito filimu yapulasitiki kuteteza pamwamba

• Pazitsulo zonse zosapanga dzimbiri zimadzaza ndi plywood case. Kwa kukula kwakukulu kwa kaboni flange amadzazidwa ndi plywood pallet. Kapena akhoza makonda kulongedza katundu.

• Kutumiza chizindikiro kungapange pa pempho

• Zolemba pazogulitsa zimatha kujambulidwa kapena kusindikizidwa. OEM amavomerezedwa.

KUYENDERA

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Dimension test

Asanaperekedwe, gulu lathu la QC lidzakonza mayeso a NDT ndi kuyezetsa mawonekedwe. Komanso kuvomereza TPI (kuwunika kwa gulu lachitatu).

NJIRA YOPHUNZITSA

| 1. Sankhani Genuine yaiwisi | 2. Dulani zopangira | 3. Pre-kutentha |

| 4. Kunyenga | 5. Chithandizo cha kutentha | 6. Makina Ovuta |

| 7. Kubowola | 8. Kuchita bwino | 9. Kulemba chizindikiro |

| 10. Kuyendera | 11. Kunyamula | 12. Kutumiza |

Flange yolumikizana ndi lap imafuna zigawo ziwiri za mapaipi kumbali iliyonse ya cholumikizira cholumikizira, chomangira chamkati ndi cholumikizira chokhazikika. Flange yotayirira imafika pamtunda wakunja kwa nsonga, yomwe imakhala yomangika pamapaipi. The flange kumbuyo si welded ku chitoliro, ndipo amatha kusinthasintha, zomwe zimakhala zothandiza makamaka pakufunika kuwongolera ma flanges panthawi yomanga.

Komanso, monga flange kumbuyo sichimakhudzana ndi njira yamadzimadzi, imatha kupangidwa ndi zinthu zochepa zosawononga. Mwachitsanzo, ngati ndondomekoyi ikuwononga ndipo imafuna kuti chitolirocho chikhale chachitsulo chosapanga dzimbiri, monga ASTM A312 TP316L, ndiye kuti mapeto a stub ayeneranso kupangidwa ndi SS 316L; komabe, flange yochirikiza imatha kupangidwa ndi mtengo wotsika mtengo wa ASTM A105.

Njira yolumikizirana iyi si yolimba ngati khosi la weld flange koma ndiyabwino kuposa zomata, socket weld, ndi slip pa zolumikizira; komabe, ndi okwera mtengo kwambiri kuti aphedwe, chifukwa pamafunika kuwotcherera kwathunthu koma kumafuna zigawo ziwiri.

Mapeto a Stub nthawi zonse adzagwiritsidwa ntchito ndi Lap Joint flange, ngati flange yothandizira.

Malumikizidwe a flangewa amagwiritsidwa ntchito, m'machitidwe otsika komanso osafunikira, ndipo ndi njira yotsika mtengo yopangira.

Mu dongosolo lazitsulo zosapanga dzimbiri, mwachitsanzo, chitsulo cha carbon steel flange chingagwiritsidwe ntchito, chifukwa sichimakhudzana ndi mankhwala mu chitoliro.

Ma Stub End amapezeka pafupifupi ma diameter onse a chitoliro. Makulidwe ndi kulolerana kwamitundu kumatanthauzidwa mu ASME B.16.9 muyezo. Ma Stub Ends (zowonjezera) zosagwirizana ndi kuwala kwa corrosion amatanthauzidwa mu MSS SP43.

- Ufulu woyendayenda mozungulira chitoliro umathandizira kulumikiza mabowo a flange otsutsana.

- Kupanda kukhudzana ndi madzimadzi mu chitoliro nthawi zambiri amalola ntchito yotsika mtengo mpweya zitsulo flanges ndi dzimbiri kugonjetsedwa chitoliro.

- M'makina omwe amakokoloka kapena kuwononga mwachangu, ma flanges amatha kupulumutsidwa kuti agwiritsidwenso ntchito.

Zogulitsa zikuwonetsa

1. Nkhope

nkhope yosalala, Radius ndiye yofunika kwambiri

2. Ndi likulu kapena opanda likulu

3.Kumaliza kwa nkhope

Mapeto pa nkhope ya flange amayezedwa ngati Arithmetical Average Roughness Height(AARH). Kumaliza kumatsimikiziridwa ndi muyezo womwe umagwiritsidwa ntchito. Mwachitsanzo, ANSI B16.5 imatchula mapeto a nkhope mkati mwa 125AARH-500AARH (3.2Ra mpaka 12.5Ra). Zomaliza zina zilipo pa pempho, mwachitsanzo 1.6 Ra max, 1.6 / 3.2 Ra, 3.2 / 6.3Ra kapena 6.3 / 12.5Ra. Mtundu wa 3.2 / 6.3Ra ndiwofala kwambiri.

Kulemba ndi kulongedza katundu

• Chigawo chilichonse chimagwiritsa ntchito filimu yapulasitiki kuteteza pamwamba

• Pazitsulo zonse zosapanga dzimbiri zimadzaza ndi plywood case. Kwa kukula kwakukulu kwa kaboni flange amadzazidwa ndi plywood pallet. Kapena akhoza makonda kulongedza katundu.

• Kutumiza chizindikiro kungapange pa pempho

• Zolemba pazogulitsa zimatha kujambulidwa kapena kusindikizidwa. OEM amavomerezedwa.

Kuyendera

• Kuyesa kwa UT

• Kuyesa kwa PT

• Mayeso a MT

• Dimension test

Asanaperekedwe, gulu lathu la QC lidzakonza mayeso a NDT ndi kuyezetsa mawonekedwe. Komanso kuvomereza TPI (kuwunika kwa gulu lachitatu).

Njira yopanga

| 1. Sankhani Genuine yaiwisi | 2. Dulani zopangira | 3. Pre-kutentha |

| 4. Kunyenga | 5. Chithandizo cha kutentha | 6. Makina Ovuta |

| 7. Kubowola | 8. Kuchita bwino | 9. Kulemba chizindikiro |

| 10. Kuyendera | 11. Kunyamula | 12. Kutumiza |

-

ASTM A182 F51 F53 BL ANSI B16.5 Chitsulo chosapanga dzimbiri...

-

A105 150lb Dn150 mpweya zitsulo kuwotcherera pozembera pa f ...

-

Wopanga mwaukadaulo wopangira kuthamanga kwambiri ...

-

paddle opanda spacer A515 gr 60 chithunzi 8 chiwonetsero ...

-

ASME b16.48 Factory Sale carbon steel chithunzi 8 ...

-

carbon steel a105 forge blind BL flange